| |

| |

NUOVE GRAFICHE PUDDU installs ‘unique’ LABELTECH, E+L combination.

July 2016: NUOVE GRAFICHE PUDDU, an Italian label company based near Cagliari on the Italian island of Sardinia, has invested in a LABELTECH ORTLES 330 slitter rewinder, which has been equipped with an ERHARDT+LEIMER SMARTSCAN S camera system.

The improved ORTLES user interface with step-by-step instruction and the quick SMARTSCAN S setup permits the fastest and easiest possible job start-up.

This is the first time this kind of camera has been combined with a LABELTECH rewinder, and is said to create a very efficient and cost effective option for label inspection and finishing.

Both LABELTECH and E+L worked hard to prepare the machine in record time, satisfying the short delivery time specified by customer of three weeks.

In September LABELTECH will install another SMARTSCAN S onto a recent installation of an ORTLES 430 and EIGER 430, reproducing a wider version of the configuration presented at the past Labelexpo Europe in 2015.

|

|

| |

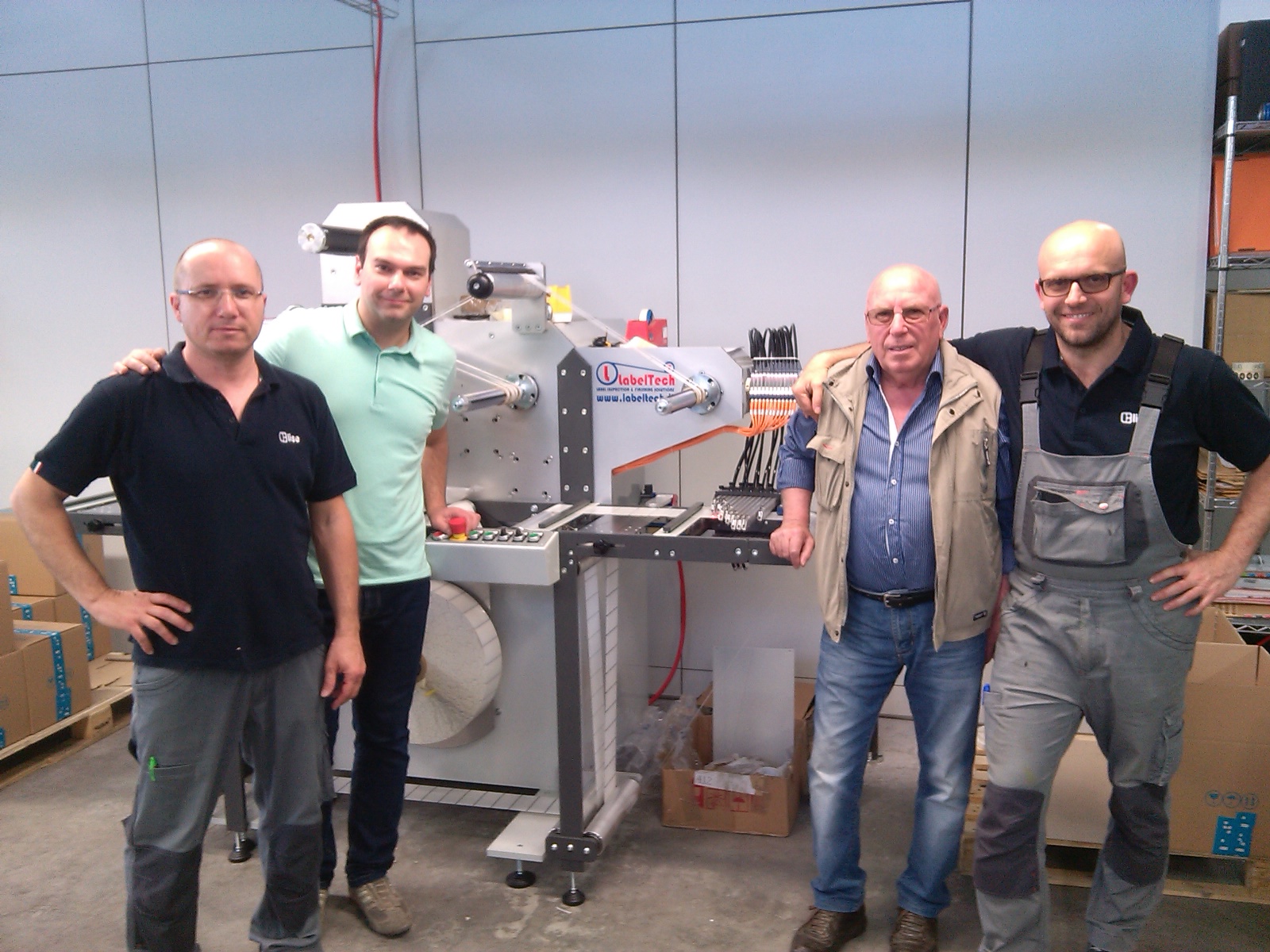

LISE ETICHETTE installs a LABELTECH IT350 triple rewinder inspection machine.

June 2016: A special version of LABELTECH IT350 slitter rewinder has been developed and delivered to LISE ETICHETTE, a dynamic label company based in Siracusa, Sicily.

The servo driven third rewinder, placed right at the top of the slitting unit, can be used either as lateral trims rewinder and as waste rewinder. This custom develop can be now considered as a standard optional and can be installed on all LABELTECH rewinders.

"Rewinding the trims permits us to have a more compact waste, so the third rewinder developed for us by LABELTECH under our specifications allows us to achieve this target and the dual function expands its usage in mostly all machine jobs " said mr Linguanti, owner of the company.

In addition we found out that the payback of this accessory will be shorter than expected, due to the less power consumption if compared to a traditional trim extractor.

"Our machines are custom manufactured, configured, and tested to meet the specific needs of each of our clients. We are always interested in cooperating and sharing knowledge with them and often, as not only in this occasion but also for example for the FuruPlus, the result is a new and useful tool that enter in our optional list." said Eng. D'Onofrio LABELTECH G.M.

|

|

| |

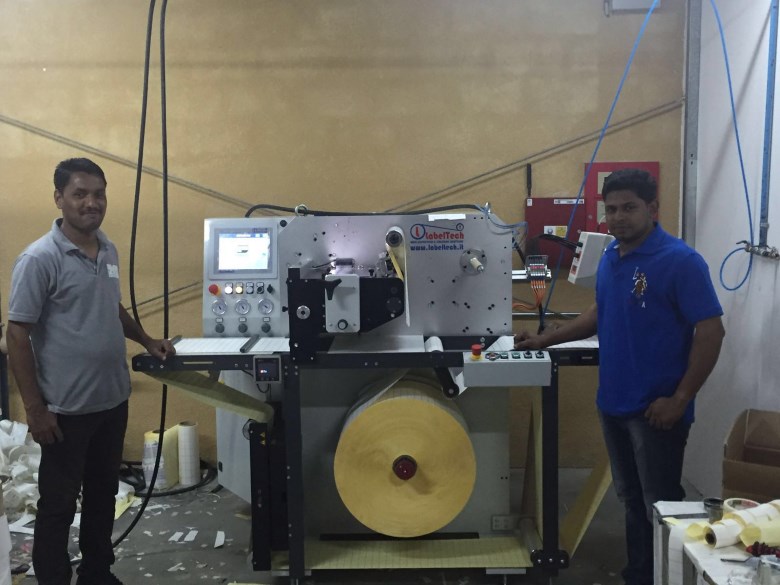

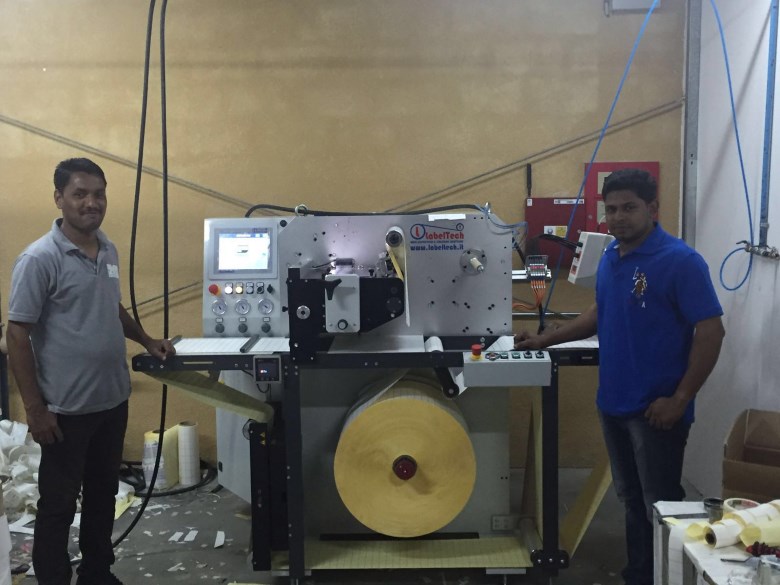

LABELTECH installs its first slitter rewinder in Middle East.

May 2016: ALI ALHASHEMI TRADING CO llc, U.A.E. representative of LABELTECH, has sold the first LABELTECH IT350 slitter rewinder inspection machine to PRINT PACK LABELS INDUSTRY.

Dubai based label printer PRINT PACK LABELS INDUSTRY has added a LABELTECH IT350 slitter rewinder inspection machine to its machine portfolio; the machine is equipped with 2 in 1 slitter system, stroboscope lamp and LABELTECH Furu inspection system.

The machine purchase is addressed to support the constant growing of the company, enhancing its productivity in response of its customers' increasing demand.

Mr Sujit Gaikwad from ALI ALHASHEMI TRADING CO, the local LABELTECH distributor in U.A.E., led installation and training along with Mr. Fabio Tocco LABELTECH Technical Chief.

"LABELTECH & ALI ALHASHEMI team has done a commendable job, we are thankful for all the hard work, technical support & timely assistance they have put in slitting machine installation project. Thanks again for your professionalism, we appreciate your service" PRINT PACK LABELS INDUSTRY company management affirmed.

Mr Sujit Gaikwad from ALI ALHASHEMI trading Co said "We are thankful to LABELTECH for their trustworthy collaboration with ALI ALHASHEMI TRADING CO- The solution which LABELTECH offers will help the local label printers to achieve their goals and work with brands."

"I found LABELTECH machines very operating friendly & simple to understand yet very effective in terms of finished rolls. We can now strongly enter into label industry of Middle East along with LABELTECH finishing machine.

First successful installation in Middle East & customer was really happy for having great support from Eng. Gabriele D’Onofrio G.M. of LABELTECH & Mr. Fabio Tocco Technical Chief of LABELTECH" he added. .

LABELTECH and ALI ALHASHEMI trading Co llc have strengthened their collaboration during Labelexpo Europe 2015.

" We are delighted to partner with ALI ALHASHEMI who has a rich experience in all fields of label printing and offers an excellent technical support" Eng. Gabriele D'Onofrio G.M. of LABELTECH said, " we expect to sell other machines in this market by the end of the year".

|

|

| |

The wait is over : SCILIAR is now available

The wait is over : SCILIAR is now available

April 2016: first SCILIAR bidirectional rewinder horizontal has been delivered.

Sciliar is equipped with colour touch screen, automatic tension control, label/meter/diameter counter and missing label detection.

The nip roll, not provided on other machines of this kind, is the distinguishing feature that makes this machine stand out .

The nip roll permits a perfect rewinding and speed management, automatic diameter calculation and excellent tension .

Tension increments proportionally with the reel diameter growth, following the accurate algorithms developed for LABELTECH ORTLES slitter rewinder inspection machine.

SCILIAR has been designed to combine the high quality of sophisticated slitter rewinders and the versatility of common table-top rewinders.

More technical details are available here

|

|

| |

Italian printer RILIEVOGRAFIA FIAMMENGHI installs first EIGER die-cut to register unit

Italian printer RILIEVOGRAFIA FIAMMENGHI installs first EIGER die-cut to register unit

March 2015: Working in line with an IT450 slitter rewinder, EIGER meets high requirement in die-cutting quality and register control.

EIGER was launched at Labelexpo Europe 2015.

‘The LABELTECH equipment will help to increase our production and to provide an excellent service to our clients,’ said Andrea Fiammenghi, owner of RILIEVOGRAFIA FIAMMENGHI .

‘In addition the machine mounts an ERHARDT+LEIMER NYSCAN 100 percent inspection camera, and offers us a complete solution for producing finished and quality checked label rolls in just one step, sparing time and increasing productivity.’

|

|

| |

Looking ahead to 2016

Jan 2015: Early 2016 the new HORIZONTAL TABLE TOP REWINDER SCILIAR will be launched.

The majority of the table top rewinders on market has big lack of features: very poor rewinding tension quality, bad slow down/stop at end of roll, no splicing tools etc. and a good label company cannot accept this, as a re-rewinded roll must have the same characteristics of a roll processed just on a slitter/rewinder.

This need push LABELTECH to develop SCILIAR, this machine combines the high quality of the sophisticated slitter/rewinders and the versatility of the common table top rewinders.

SCILIAR main features are:

- Servo drive technology on unwinder, nip roll and rewinder (3 completely independent motorizations)

- Bi-directional rewinding with internal/external unwinding and rewinding sense

- Max speed 100m/min

- Interchangeable unwinder and rewinder air shafts

- Splicing table with pneumatic clamps

- 7” color touch screen

- Ultrasonic label counter for every kind of supported material

- Area for host options such as camera, inkjet marking printer etc

- Web width: 260mm

The first SCILIAR has been already sold and will be installed in Moscow at the beginning of May.

|

|

| |

Season's Greetings!

Dec 15: reetings of the Season from all of us at LABELTECH and Best Wishes for the New Year.

2015 has been a great year, we launched the new EIGER330,

we took part to a record edition of LABELEXPO EUROPE ,

the most exciting and rewarding since Labeltech has been exhibiting

and thanks to our agents we have strengthen our position on market.

|

|

| |

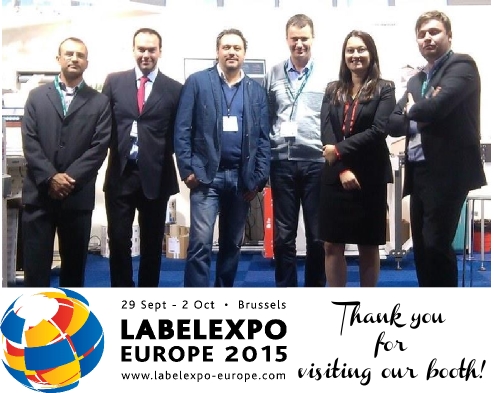

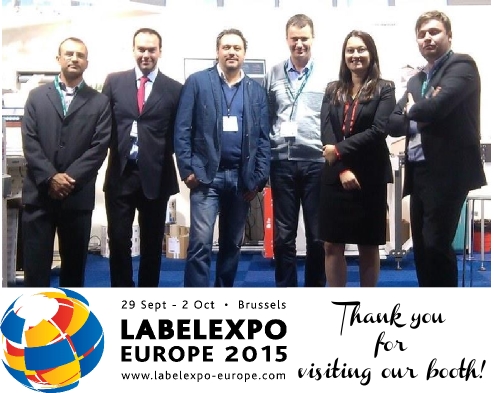

Great to have been part of a record edition of Labelexpo!

Great to have been part of a record edition of Labelexpo!

Oct 15: Labeltech has reported a successful Labelexpo during which the new EIGER330 die cut to register unit has been launched.

The 35th Labelexpo will be remembered as a record edition, 35,739 visitors from 146 countries, over 650 exhibitors.

Ilaria Fenino Labeltech's sales manager commented

"Labelexpo 2015 was the most exciting and rewarding since Labeltech has

been exhibiting, we couldn't be happier with the results! We were

overwhelmed with the record breaking amount of sales leads taken!"

The launch of the new Eiger 330 die cut to register unit was extremely well received.

"Visitors to our stand acknowledged and complimented the performance

and innovative features of our new Eiger 330 die cut to register unit" said Gabriele D'Onofrio Labeltech's General Manager "the gearless die-cut and the fast and easy job start up received a really positive feedback from show attendees."

OUR SINCERE THANKS

Labeltech would like to thank its agents, Gian Luca, Eduard, Cesar, Alexey, Sujit, Martin and Dave and its partners at Labelexpo, UPM_Raflatac, RotoMetrics, NuMaber, WBS_Ink, SummitPress and Packlist that contributed in making Labelexpo Europe 2015 its best ever.

A big thank you to all visitors that showed interest in our products, you made Labelexpo Europe 2015 a success for LABELTECH. We are already looking forward to Labelexpo 2017 where you can be sure to see even more innovation from Labeltech!

|

|

| |

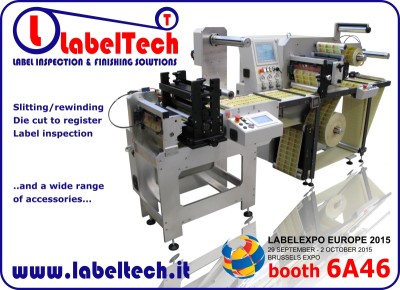

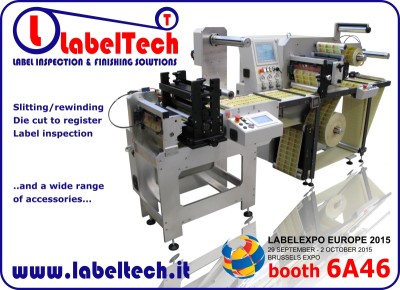

Labeltech at Labelexpo Hall 6 Stand A46

Labeltech at Labelexpo Hall 6 Stand A46

Sept 2015: At Labelexpo booth 6A46, Labeltech will launch the new die cut to register unit EIGER330 combined with an IT350 slitter/rewinder

with double rewinder and new E+L inspection system Smartscan.

Full article on Labelexpo website

|

|

| |

10th Installation for Labeltech @ CCL-Kontur Russia

Aug 2015: An important achievement has been reached few days ago: Prisma R2R

, Labeltech russian agent, installed the 10th Labeltech rewinder at CCL-Kontur Russia, Moscow site.

Labeltech is a long time partner for CCL-Kontur that is working with

its machines for more than 10 years, appreciating its performances and

durability.

In July CCL-Kontur confirmed its trust in Labeltech incrementing its

machine portfolio with this new fully equipped IT450 series 5.

"The

continuing preference accorded to us from such an important company

like CCL-Kontur it's a big point of honor for us and It's a pleasure to

serve CCL-Kontur once again "

says Eduard Galperin, Prisma R2R general manager "CCL-Kontur

staff can appreciate the latest innovation introduced in the new series

5 before the official presentation at the forthcoming Labelexpo Europe" added.

The configuration includes dual rewinder, waste rewinder, dual slitting

system (razor and rotary) and AVT Helios 100% inspection camera.

|

|

| |

EIGER 330: the new die cut unit

EIGER330, the new and innovative Labeltech solution for die cut labels

Labeltech presents EIGER330, the new DIE-CUT TO REGISTER machine: a

full rotary unit that works in-line with Labeltech rewinder to provide

the ideal solution for digital jobs. This innovative machine mounts the

latest BOSCH REXROTH technology to ensure the maximum efficiency,

reliability and performance level available at the state of the art. To

reach the best accuracy the gearless die cut station, the matrix

rewinder and the nip roll have 3 dedicated brushless motors. With its

compact size (only 1,2m long!!) it will be easy to transform a simple

slitter/rewinder in a finishing machine. EIGER's independent electronic

permits to connect it on third part rewinder with a very little effort.

click here for more info !

|

|

| |

PRISMA @ PRINTECH 2015 - MOSCOW

PRISMA @ PRINTECH 2015 - MOSCOW

June 2015: Prisma R2R , Labeltech official partner for russian market is exhibiting at the Printech 2015, International exhibition

of Equipment, Technologies and Supplies for Print and Advertising Production at booth C613. Another great opportunity to collect informations about our slitter/rewinder and other Labeltech products.

The exibithion takes place at Moscow's "Crocus Expo" 16 - 19 June 2015, Pavilion 1.

Come and join us there! !

|

|

| |

Converflex press release

Converflex press release

In occasion of Converflex 2015, Labeltech issue a press release

regarding the succesful cooperation with E+L started in 2014, here

below you can find the full text:

ERHARDT+LEIMER & LABELTECH, a successful cooperation

2014 has seen a successful cooperation between LABELTECH and E+L with

several installations in the national and international market.

The improved features of LABELTECH series five provides a more

comfortable roll handling and a quicker slitter setup. The E+L

products, from a simple missing label camera to the advanced NYSCAN

100% inspection system off line and on printing machine (workflow)

permitted to satisfy the different customer requirements in the best

and most efficient way.

“The combination between the two systems came out very easy, almost if

they’re designed to fit together!” says Gabriele D’Onofrio, general

manager of LABELTECH. “The installation of any E+L device is effortless

and the interface provides an efficient defect management”.

“When I come to client’s facility the day after a LABELTECH startup I

always find a skilled operator already well prepared on slitter

management, so focused to learn inspection camera features. In just two

days the task is done!” added Giampietro Conconi, area sales manager

for E+L´s vision products. Highlighting the easiness of the whole

operator training “An advanced feature that distinguishes NYSCAN from

the competitors devices is the possibility to detect even a white write

printed on a clear label placed on a white silicon substrate”. Another

big advantage is the unique and patended LED illumination TubeLight

which allows customers to inspect difficult but typical materials like

hot and cold foil, embossing, metalized and reflective material or

holograms without having any “pseudo” defects.

Grafiche Pradella , a company with three generations of

experience in label industry is one of the partners that chose E+L

NYSCAN & LABELTECH rewinder in 2014 to assure a 100% control on

every single self adhesive label that came out from their facility.

Italian label printer Indet srl,

whom equipment portfolio includes three LABELTECH slitter rewinders,

installed a E+L workflow system between their new flexo machine and the

newest LABELTECH IT450 they have, adopting this new trendy technology

that allow an optimized factory production integration. They are happy

that they are able now to use their LABELTECH rewinder on high speed

without having any speed limitations based on 100% inspection systems.

And with their first evaluations they see the quick return of

investment based on improvements like waste reduction on the press,

increasing productivity and winning new customers.

Label printer Tipolitografia MP

based in Alba, Italy has improved its LABELTECH IT350 finishing machine

with an ELCAM camera-based Matrix and Missing Label Detection that

allows to process any missing and matrix detection on the finest

designed wine label, including clear on clear with a tiny elegant hot

foil.

The 2015 started with already a couple of contracts signed for the two

companies, assuring another exciting year of cooperation.

|

|

| |

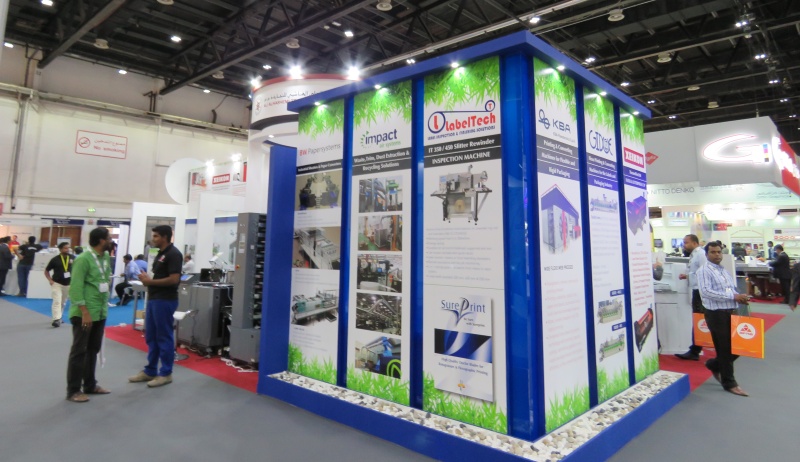

Gulf Print Pack: Labeltech enters in Middle East Market

Gulf Print Pack: Labeltech enters in Middle East Market

May 2015: thanks to the cooperation con his agent for middle east ALI ALHASHEMI TRADING EST, Labeltech enters in Middle East Market.

The occasion is the Gulf Print Pack 2015, 13-16 april in Dubai.

Gulf Print & Pack is the leading event for commercial and package

printers in the Middle East and North Africa, ALI ALASHEMI TRADING EST

is a point of reference in the printing industry for this area and his

250sqm booth at this exibhition is the ideal showcase to present for

the first time Labeltech products.

Meet there our agent at booth B1

|

|

|

The wait is over : SCILIAR is now available

The wait is over : SCILIAR is now available

Labeltech at Labelexpo Hall 6 Stand A46

Labeltech at Labelexpo Hall 6 Stand A46

PRISMA @ PRINTECH 2015 - MOSCOW

PRISMA @ PRINTECH 2015 - MOSCOW  Converflex press release

Converflex press release

Italian printer RILIEVOGRAFIA FIAMMENGHI installs first EIGER die-cut to register unit

Italian printer RILIEVOGRAFIA FIAMMENGHI installs first EIGER die-cut to register unit  Great to have been part of a record edition of Labelexpo!

Great to have been part of a record edition of Labelexpo!  Gulf Print Pack: Labeltech enters in Middle East Market

Gulf Print Pack: Labeltech enters in Middle East Market