Inspection, cutting and rewinding table

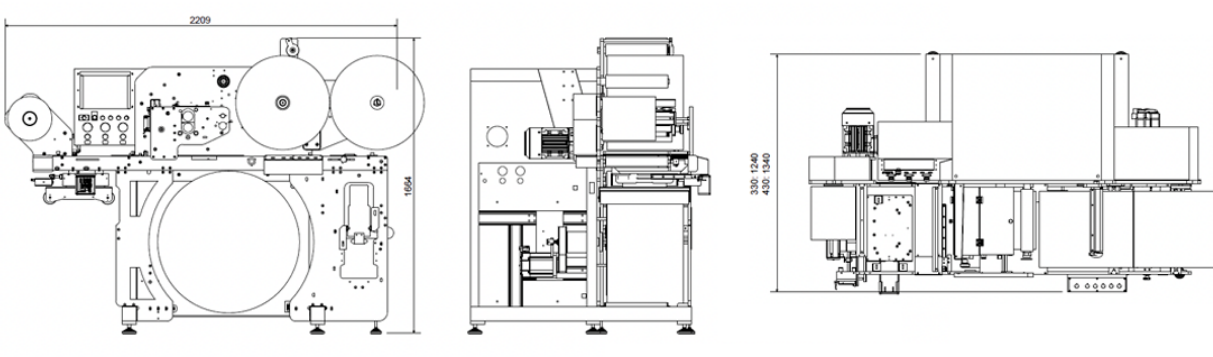

Ortles

Inspection slitter rewinder for average/long runs from flexo, offset or inkjet

Main features

- BOSCH REXROTH electronics, servo drive motors on nip roll and rewinders

- Servo driven 800mm unwinder with Energy recovery, for a significative cost saving

- Webguide with ultrasonic sensor

- Rewinding speed up to 350m/min

- Display 10” color touch screen with step by step instructions

- Storable job recipes with quick recall by name, customer and favourites

- Remote service and production data export

- Stop production with label counter, length and final diameter

- Automatic stop at unwinder end of roll

- Ultrasonic label counter

- 2 in 1 slitting system, to pass from rotary to razor in few minutes with no additional devices

- Rewinder with servo drive motorization

- Available size 330mm, 430mm, 530mm

Available optionals

- Second rewinder with independent servo drive motorization

- LAVAREDO automatic slitter positioning system for both rotary and razor

- 100% inspection system

- Waste rewinder with inverter motorization

- Motorized trim extractor synchronized with web movement

- Marcatore inkjet per dati variabili, datamatrix ecc

- Expandable shafts from 0,5” to 6”

- Longitudinal razor slittng unit

- Full rotary die cut unit EIGER